About Viking Pump Hygienic

Viking Pump Hygienic is one of the world’s leading manufacturers of hygienic rotary lobe and circumferential piston pumps. These are designed to meet the requirements of the food & beverage, pharmaceutical and biopharmaceutical industries. Whatever the challenges of your process, one of our world-class pumps can offer a solution.

Viking Pump Hygienic has a global presence, with manufacturing sites in Cedar Falls, Iowa, USA and Eastbourne, UK. Cedar Falls is the home of Viking Pump, and Eastbourne is at the centre of hygienic pump manufacturing in the UK and Europe. Formerly known as Johnson Pump (UK), the company has been long-established in Eastbourne, having manufactured and developed products here since 1983.

The product range is designed to provide the ultimate in reliability in critical applications that demand gentle product handling, with many pumps having a documented service life of several decades. Complete stainless steel lobe pumps with non-contacting design and circumferential piston pumps with innovative non-galling alloy rotors are backed up by heavy-duty gearboxes and generously dimensioned shafts and bearings. Pumps are designed with maintenance in mind and are therefore easy to strip and rebuild, with spare parts and expert advice readily available.

Hygienic Pumps

Viking Pump Hygienic pump range offers the best efficiency and a wide range of porting, cleaning, and sealing options to meet your needs. In a business where cleanliness is key to reduce cross-contamination, we offer CIP (clean in place), SIP (sanitize in place), and COP (clean out of place) pumps to save you time and effort.

Viking Pump Hygienic pumps are designed to meet the highest standards of hygiene and cleanliness, making them ideal for applications in the food, beverage, pharmaceutical, and cosmetic industries. With a focus on quality and reliability, these pumps ensure the safe and efficient transfer of sensitive products while maintaining strict hygiene protocols.

Rotary Lobe Range

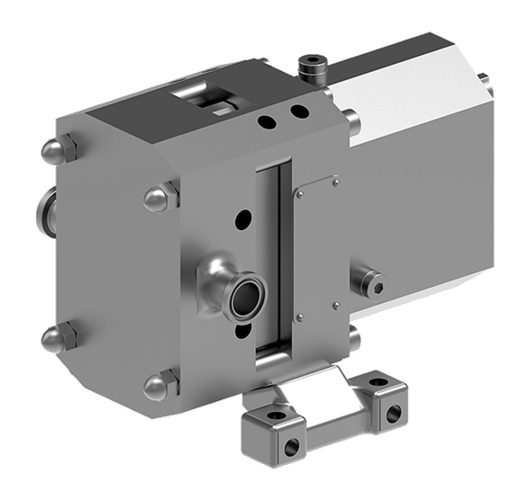

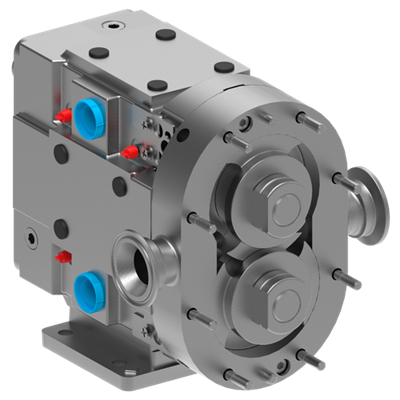

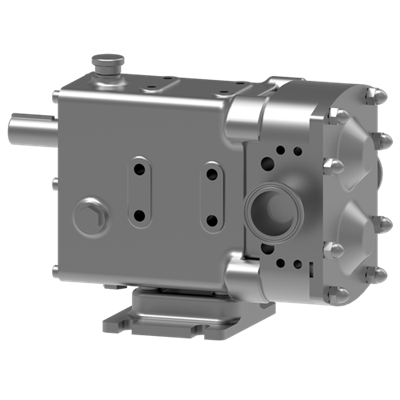

Classic+ Series Lobe Pump

The Classic+ Series™ / MultiPump® Series builds on the success of the original Classic pump, and is the perfect solution for many food production, health and beauty and pharmaceutical production applications.

Cleanable and maintenance-friendly, this range provides Viking Pump Hygienics’s greatest flow rate range of up to 832 GPM (189 m³/h) across 11 pump models with connection sizes from 1” to 6”.

More Info

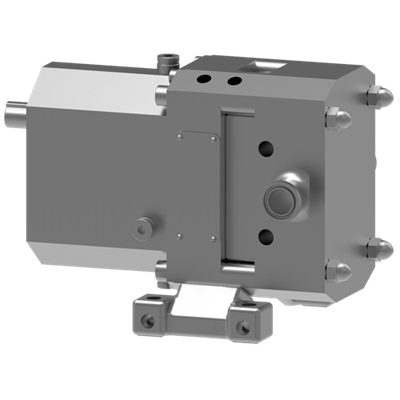

Sterilobe Series Hygienic Pump

The SteriLobe® Series pump is the premier solution for critical applications in the pharmaceutical and biopharmaceutical industries. It provides the ultimate in cleanability, with a range of industry-specific options, executions and certifications available. 14 pump models are available, providing a wide range of solutions..

More Info

Circumferential Pump Range

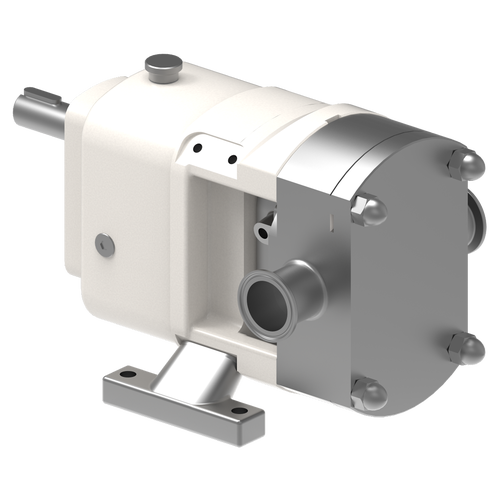

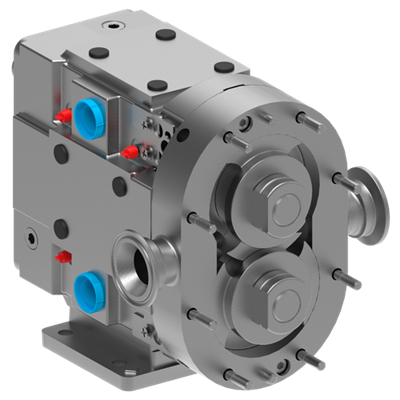

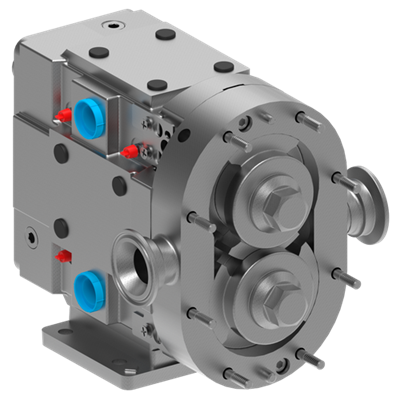

Revolution Series

The Revolution® Series represents the pinnacle of circumferential piston pump design, with seal chambers that that provide seamless upgrade potential and enhanced ease of maintenance. It is perfect for use across hygienic industries which demand high pressure capabilities, non-galling rotors and exceptional CIP capability. The Revolution® Series is available with many of the innovative options from the SteriLobe® Series, making it a unique proposition in the CPP market. This pump series can handle flows up to 399 GPM (91 m³/h) and pressures up to 450 PSI (31 bar).

More Info

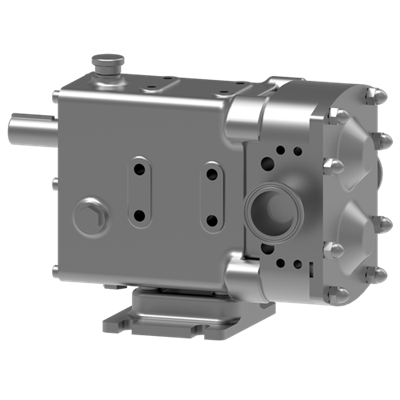

TRA10 Series

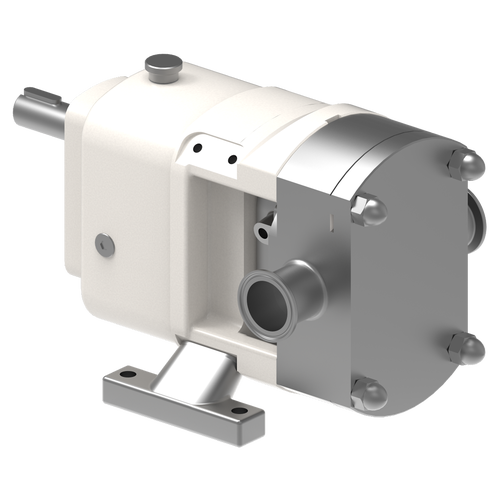

The TRA®10 Series is a time-served and robust classic of circumferential piston pump design, manufactured to 3A standards. Available with mechanicals seals or o-ring seals, it is the ideal solution for dairy, bakery, meat processing, and more due to its cleanability and efficiency. Interchangeable with comparable competitor products, this range provides continuity and stability in your process.

This pump can handle flows up to 450 GPM (102 m³/h) and pressures up to 400 PSI (27 bar).

More Info

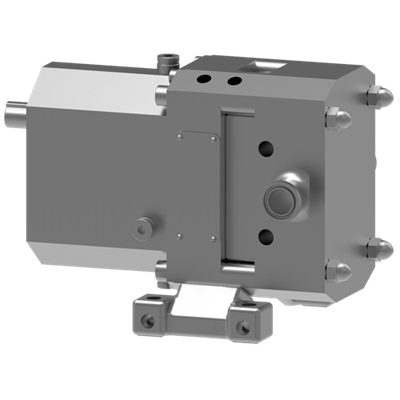

TRA20 Series

The TRA®20 Series has enhanced design, providing greater pressures and even easier maintenance as standard, manufactured to 3A standards. Like the TRA®10 Series hygienic pump, this is an excellent solution for dairy, bakery, meat processing, and more due to its cleanability and efficiency. Interchangeable with comparable competitor products, this range provides continuity and stability in your process.

This pump can handle flows up to 450 GPM (102 m³/h) and pressures up to 450 PSI (31 bar).

More Info

Case Studies

Hygienic lobe pumps for food manufacturer

We recently received a repeat order for six CP10 hygienic rotary lobe pumps from Viking Pump Hygienic, destined for a manufacturer of food processing equipment.

The Classic+ lobe pump range features timed, non-contacting rotors to minimise shear, a modular pump design for easy disassembly, and helical timing gears for high torque and quieter operation, extending the pump's lifespan.

The Classic+ series is known for its durability and reliability, making it a popular choice among food & drink, cosmetic, and pharmaceutical customers across the UK.

Hygienic lobe pumps for pet food manufacturer

From bakeries to breweries and from sausages to sauces, hygienic pumps play a vital role in the food and beverage industries. These pumps are not just important for human food production; our furry friends also deserve the same level of quality and hygiene in their meals.

That's why this CP10 rotary lobe pump from Viking Pump® Hygienic is on its way to one of the UK's leading pet food manufacturers. With a 316L stainless steel casing and 1" tri-clamp connections, this Classic+ model is long-coupled to a 0.55 kW Nord gear motor and mounted on a stainless-steel baseplate.

About Us

Michael Smith Engineers Ltd was formed in 1971 as a specialist pump distributor. We have our Head Office and workshop in Woking, Surrey and a Sales and Support office in Cleckheaton, West Yorkshire, as well as staff located in Derbyshire and Glasgow, allowing us to provide service and support to customers across the United Kingdom. With over 18 years experience distributing, repairing and servicing Viking Pumps, we have recently been appointed distributors for the Viking Pump Hygienic range of pumps. We provide engineered pump set builds, including motors and gearboxes with specialist fabricated baseplates and shrouds, with a wide range of installation options to suit any production environment. Contact our applications team for expert advice on processes and pump selections.

What Our Customers Say

"MSE’s support has been invaluable in assisting us with our pumping needs; we trust their technical expertise."

Peter Hanratty

Baker Perkins

"With reliable service from MSE, Viking Pumps are a vital and integral part of our production plant. Through the advancement of Viking’s modular version of this rugged, robust pump, we will see future lifecycle costs reduced."

Steve Williams

Stepan UK

"Overall, I would describe Michael Smith Engineers Ltd as one of our best performing vendors."

Richard Smith

Harman Technology Ltd